Whole Plant Planning

Equipment Customization

Maintenance and Upgrades

Consulting and Answers

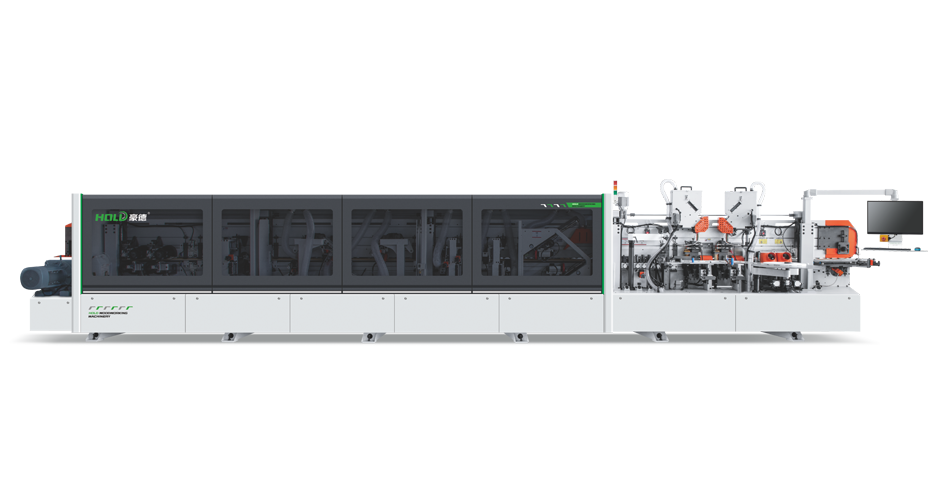

We analyze and understand customer requirements based on market positioning, product positioning, and production capacity positioning, establishing data support to develop optimal solutions.

Based on customer requirements, we customize production workshop configurations from workshop zoning, equipment layout, to personnel deployment.

HOLD assists in setting up factory facilities with professional advice on electrical layout compliant with production standards, raw material preparation, custom matching, material handling, and dust treatment.

HOLD integrates customer demand analysis results to establish customized processing test centers, monitoring product processing effects in real-time to ensure consistent high quality of customer products.

Tel:+6012 727 9220

+6013 772 9898

H/P:+607 4355595

+607 4355596

Address:1,JLN KOTA MURNI, TMN INS KOTA MURNI, OFF JLN MINYAK BEKU, 83000 BATU PAHAT, JOHOR.