Efficient - Intelligent 丨Howard Intelligent Three-dimensional Sorting Warehouse

亮点析解

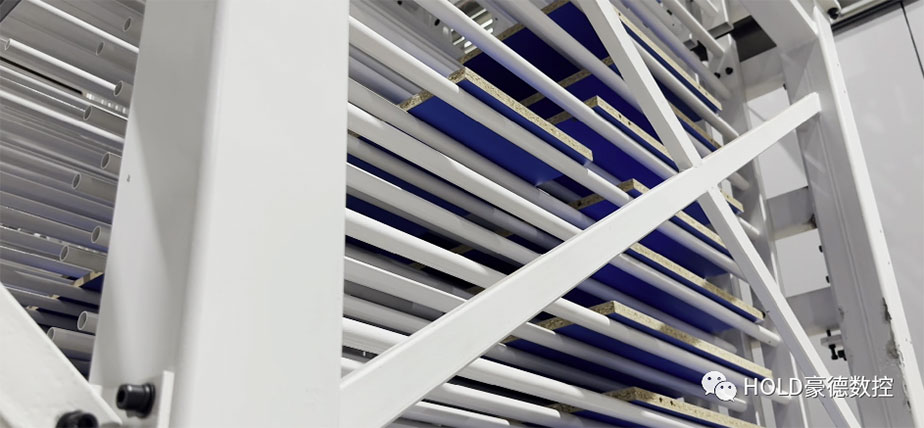

Four hoists working together

According to the size of the board, each hoist can work independently or in co-operation.

Maximum sheet size: 2800x1200mm

Minimum sheet size: 250x80mm

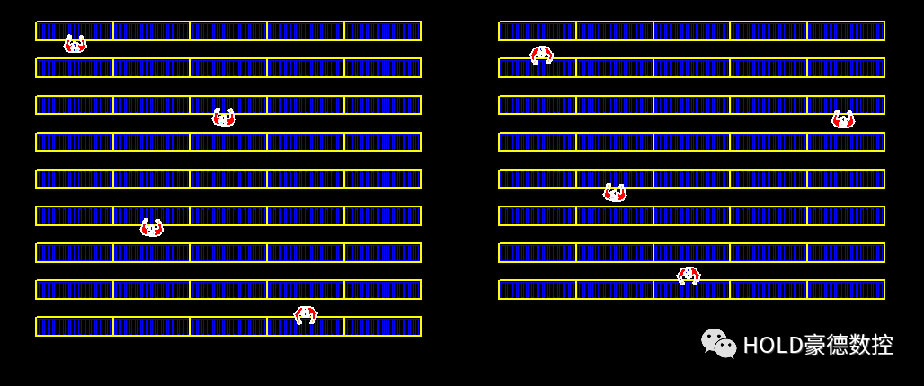

Separate work for feeding and discharging

Feeding roller and discharging roller work separately for higher efficiency.

Two rows of cache scheduling bins

Each bin has a maximum width of 1220 mm and can accommodate up to two rows of panels depending on the size of the panels.

Advantages

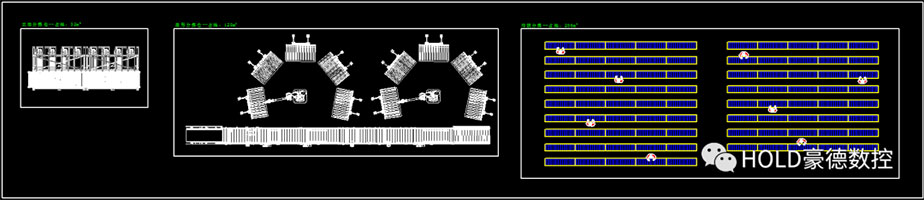

Traditional flat sorting

High labour costs, large floor space and low sorting efficiency.

Book shelf sorting

人工成本低,占地中等,设备成本高,分拣效率较低。

立体分拣仓

Efficiency capacity →

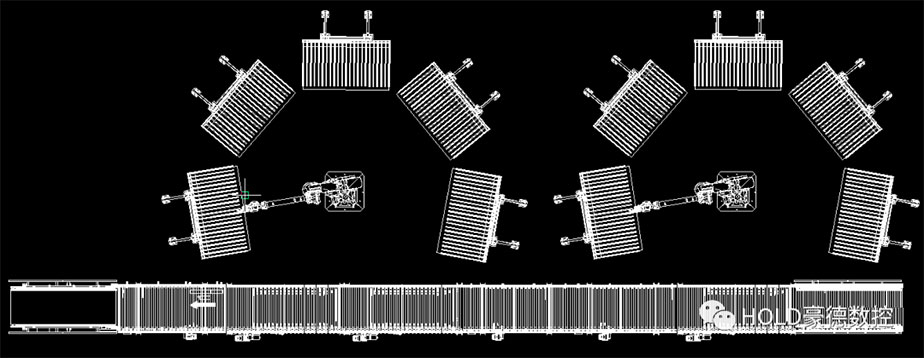

※2 sets of three-dimensional sorting bins (8 lifts

※The 2 sets of three-dimensional sorting bins can produce 8-12 boards per minute.

Inventory volume →

※2 sets of three-dimensional sorting bins maximum number of bins 288x2=576 bins.

Floor space

※Two sets of three-dimensional sorting bins cover an area of 34 square metres.

Compared with book shelf sorting, the floor space is reduced by 75%.

Compared with flat sorting, the floor space is reduced by more than 90%.

Sorting to package

Sorting to packages can be done according to orders.