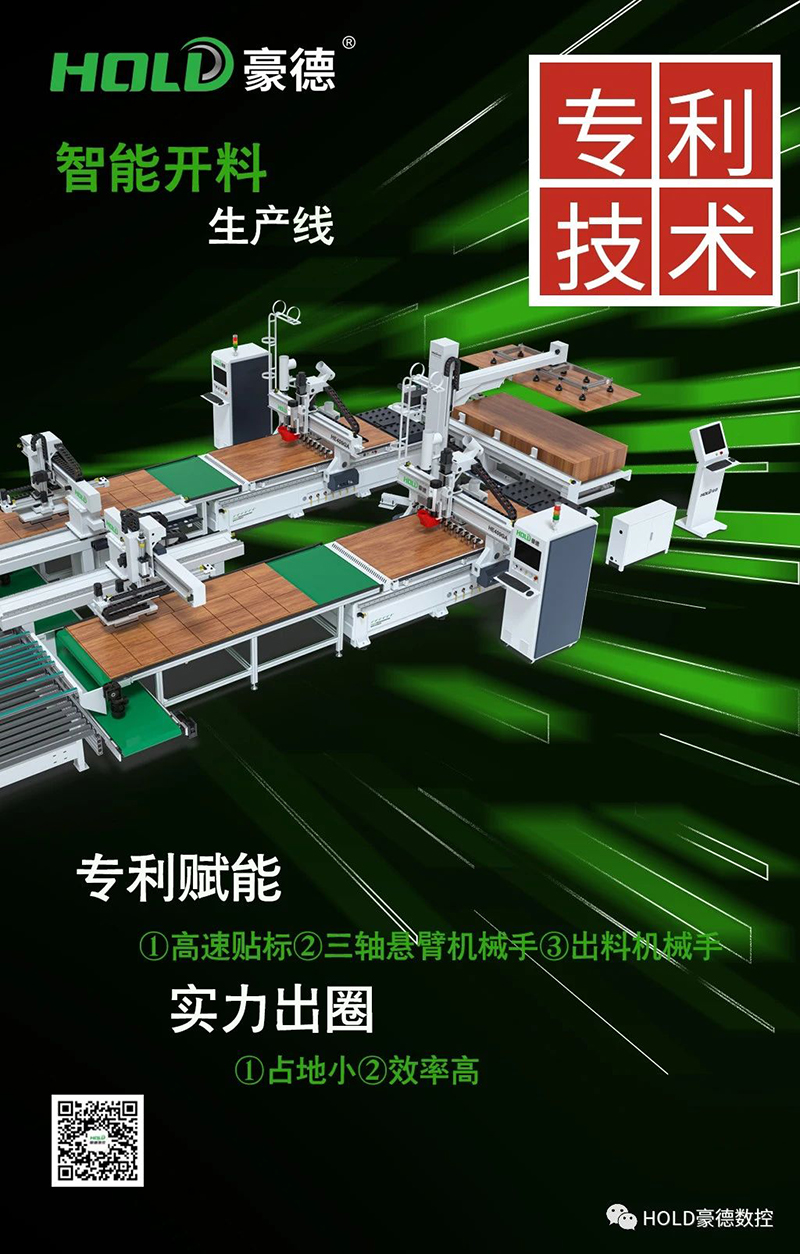

A breakthrough in traditional technology|Holder Intelligent Unwinding Line

High-speed alternating labelling

Patented double labelling mechanism

Dual labelling mechanism, alternating cycle labelling.

Pre-labelling, no waiting, up to 16 labels/minute.

Alternate independent work

Double labelling adopts synchronous belt drive, no interference with each other, 50% higher efficiency than separate labelling.

Reduce the frequency of board loading

Optional trenchless high body design, can stack the whole 18mm boards (50 sheets).

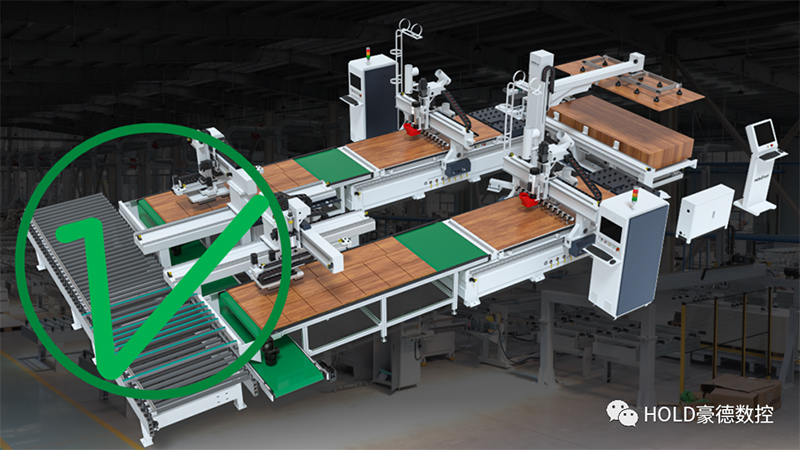

Three-axis cantilever manipulator

Dedicated machine

Each machine is equipped with a special sorting robot, which grips workpieces independently without interfering with each other.

Efficient gripping

Each group of manipulator can gripping 6 pieces/minute.

It can pick up small boards of 50x300mm.

It can also pick up the whole board.

Unloading jacking device

Two loading robots can load out the material at the same time without interfering with each other, doubling the efficiency.

Strength out of the circle

Small footprint

Compared with the traditional opening machine workstation, the labelling process to the opening process does not require roller transmission, compact structure, reducing the footprint space.

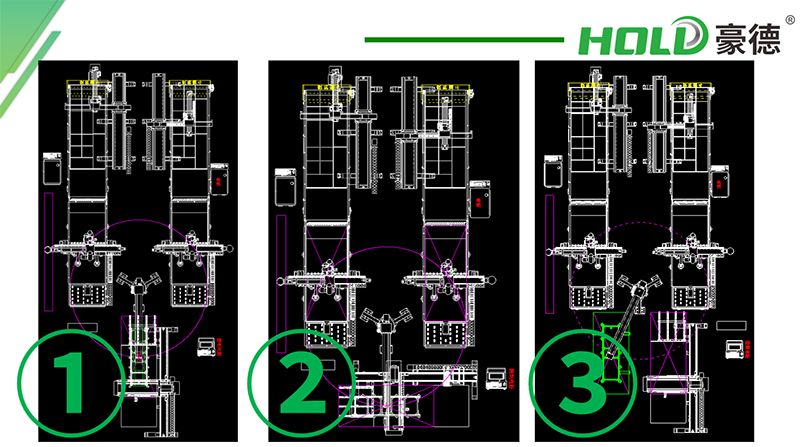

Flexible loading

variety of loading methods, according to the requirements of the customer site, to provide customers with the optimal layout

。

vSolve the pain point of vacuuming

The opener comes standard with an automatic cleaning mechanism to ensure clean boards.